Facility

Computerization of production management and introduction of advanced technology have greatly reduced costs, ensuring that we are able to deliver clients the best quality of products at the best price on time.

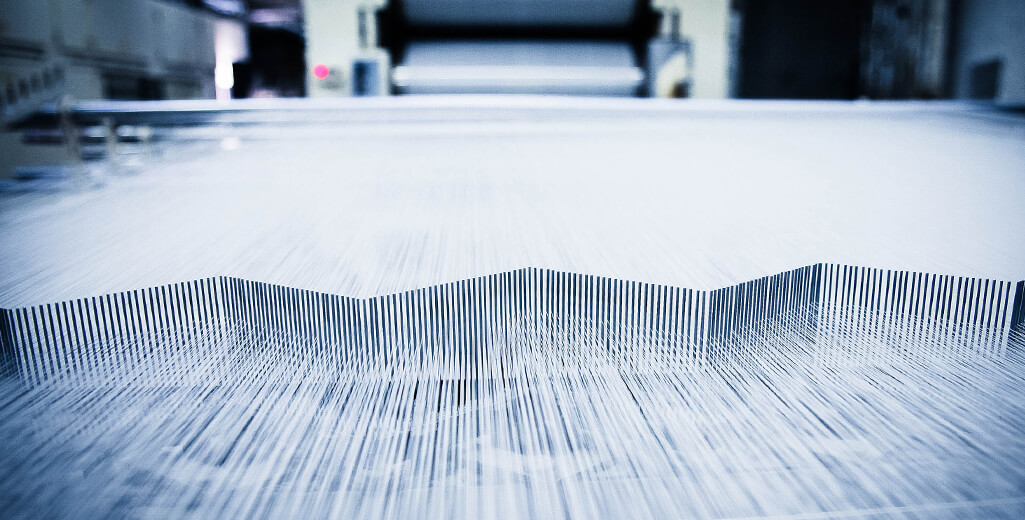

Weaving Mill

The 45,000 sq-m weaving mill is equipped with 240 Picanol (Belgium) jet weaving machines, 3 Benninger (Switzerland) sectional wrapping machines, 2 Sucker (Germany) sizing machines and 280 shuttle weaving machines. Other than that, a comprehensive test system is introduced to facilitate the production of cotton, cotton polyester, linen, rayon, tencel, nylon, corduroy, stretch twill, poplin, silk, yarn-dyed, and dobby. Each year, 36 million meters of fabric and 60 million meters of dyeing and printing fabric are produced, and another 500, 000 dozens of apparels are made.

Dyeing and Printing

With a careful selection of top suppliers from around the world, including Kyoto (Japan), Monforts (Germany), Stork (The Netherland), Lafer (Italy) and Samill (Korea), quality is ensured while the entire dyeing procedure employs auto centralization of material as well the distribution channels is controlled by an advanced computer system. The printing procedure adopted Stoke I.P.S. Delta colour 32 automatic slashing system that is supported by colour separation and wax injection with an ability to print up to 16 colorway and has increased our annual volume of production up to 60 million meters of fabric per year.

Corduroy Factory

The workshop area is 4,300 sq-m and equipped with 40 sets of Japanese advanced pile-cutting machines, 2 sets of singeing machines, and 3 sets of Brushing machines. The capacity is more than 10 million meters of corduroy every year. Strict quality control in the pile cutting process helps to ensure the quality during dyeing and printing processes.

Garment Factory

Occupying 10,000 sq-m of space, the factory is equipped with 1,500 JUKI (Japan) and Brother garment making machines, 2 auto bag opening machines, auto drafting system and draft reading machine. The annual quantity of apparel produced reaches 500,000 dozen that distributed to Europe and the States, Lai Tak is becoming the sought-after manufacturer for fashion brands.